How the Wrong ERP Can Disrupt Supply Chains

Table of Contents

CloseThe global pandemic has been a major culprit for commercial industries, and we are now beginning to see the results of months of shutdowns and quarantines. While these measures were needed to keep everyone safe and healthy, they have taken a toll on global supply chains. There is also another factor that can deeply affect the streamlined functioning of global supply, and that is working with the wrong ERP system. Manufacturers who have suffered the double impact of COVID-19 and employing the wrong ERP have learned their lesson about how working with the wrong ERP can seriously handicap business, especially in special cases where everything is not business-as-usual.

COVID-19 Supply Chain Disruptions

Residual effects from all of the shutdowns during Covid-19 are starting to hit consumers, and experts suggest that it is only going to get worse. As lockdowns and quarantines come to an end and businesses get back to full capacity, demand is going to rise, and the manufacturing sector, which is still backlogged, will struggle to keep up. The dominos fall all the way down the chain. Raw materials are unavailable due to a lack of labor, so manufacturing cannot proceed, and consumers have to wait. All of this is creating chaos for distributors and manufacturers. Already short-staffed, these companies are struggling to fill quotas. One solution taken up by many countries is an increase in domestic production, resulting in shortening supply chains. This rising trend has been called economic nationalism. The shutdowns exposed a myriad of vulnerabilities in the long global supply chains. What is worse is that this is not a one-time event. Any time there is a major disaster or disruption anywhere in the world (such as a natural disaster, war, or a pandemic), the global supply chain is bound to be impacted. Shutdowns, shortages, trade restrictions due to quarantine, and an ongoing trade war between the US and China have pressured many countries to consider their dependence on global supplies.

Areas of Delay

The major areas of delay involve raw production, manufacturing, and shipping. These can pose a challenge for managers in factories around the world. Sometimes, business owners will operate different ERP systems in different countries to meet compliance demands, due to employee know-how limitations or preferences, because of legacy systems, or financial reasons. Lacking a unified, integrated ERP solution can result in areas of delay all the way along just one company’s supply chain. Fulfillment processing is one of the biggest issues. Workers were sent home, so no one remained to fulfill orders. On top of that, everyone was homemaking purchases, so inventory demand into the supply chain was also higher than ever. With automated systems and an integrated ERP solution such as SAP S/4HANA Cloud, public edition, managers can monitor supply chains from anywhere and stay on top of progress and delays. Automation of these systems can further mean fewer delays and better forward planning.

Lack of Adequate Contingency Planning

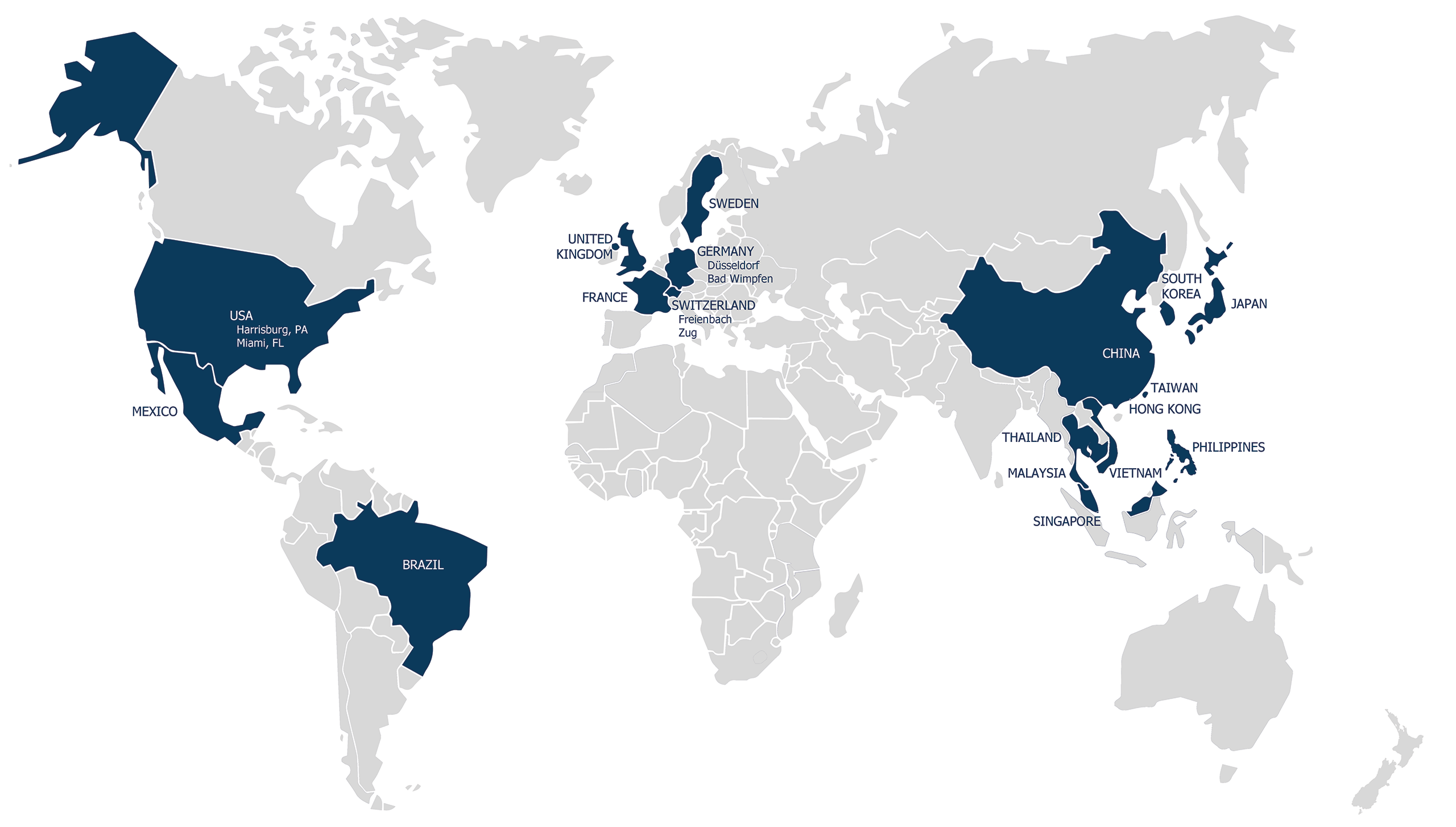

Limitations of certain ERPs are common, but they are also avoidable. Having a good partner relationship will help organizations cope with excess complexity. Once companies have the best ERP in place, the job becomes more about choosing the right solution pieces, like building blocks in a system. With this, they will be better at ensuring they are integrated in a way to optimize supply chain operations. Organizations should expect to have interruptions in any area of operations at some point in the life cycle. It is better to be prepared for a disaster that never strikes than to be struck by a disaster that you should have seen coming. By working with your ERP partner on contingency planning, you can look ahead together at what could happen in different types of scenarios and make sure to put mitigation measures in place. After all, it is during a disaster that customers become most reliant on supplies. There are many ERP options available, and there are also many ERP partners out there. Choosing the best ERP solution along with great SAP implementation partners like those at be one solutions is the best way to be prepared.

You won’t want to miss be one solutions‘ next webinar. Add your email address to be notified :

Please select your language

Welcome on be one solutions‘ websites.

Please select your language.