Manufacturing with SAP

Manufacturing made easy for your business and adaptable to your specific industry.

Tailored Solutions to Large Entreprises or Multinational Companies

Any SAP Business One user in the manufacturing industry will tell you: the software is great, but has limitations when it comes to peculiar needs. This lack of functionalities impacts day-to-day activities and overall efficacy by disrupting the existing wobbly flow. What be one solutions offers is simple: a system with the capacity of completing the missing features in SAP B1.

Manufacturing for SAP Business One

Our lean, yet powerful manufacturing add-on takes away the complexity of things. It provides easy access to one of the most vital parts of your business: Manufacturing. We let our experience from many years in the industry influence this development. be one Manufacturing is a tool that integrates seamlessly with SAP Business One and expands in a full suite that contains the following add-ons: Lean Manufacturing Core, Lean Manufacturing Terminal, Plant Maintenance & Warehouse Management (WMS).

Our Manufacturing solution, easy for the user and profitable for your operations, gets the job done.

.

be one MANUFACTURING FOR SAP BUSINESS ONE IN A NUTSHELL

- Product calculation using standard or moving average price

- Consideration of production lot size

- Run calculation in a batch run to calculate new cost prices

- Reevaluate all your items with just a few clicks from the batch calculation

- Simulate cost price changes

- Define alternative material and resources

- Assign resources to cost centers

- Split between fixed and variable cost

- Define your planned and actual hours

- Run cost center analysis reports

- Support outsourced operations process

- Choose your alternative material and resources in work order

- Control variances when closing a work order

- Run variance analysis reports

- Using terminals or handheld devices on the shop floor and warehouse

- Post material consumption

- Post production receipts

- Time consumption for resources and operators

- Down time recording and analysis

- Maintenance alerts

- Paperless handling

- Maintain your quality control test templates and inspection plans

- Maintain default batch status per item code

- Calculate shelf life

- Control of unreleased batches

- Start quality control orders to test new or expired batches

- Full or partial release of batches

- Traceability reports

- In-process quality control

- Skip lot function

- Interface to ELO Document Management System

- Keep multiple versions of item master, BOM and routing

- Choose active revision in SAP Business One

- Engineering change order workflow

- Build a new item structure (or customize an existing one) outside the SAP Business One master data objects.

- Use item / BOM / routing / resources from SBO master data, or use data that does not already exist in SAP Business One to design and calculate new products

- Real time cost and price calculation

- Powerful spreadsheet functions

- Attach new structure to quotations and sales orders in SAP Business One

- Maintain (spare parts, equipment, tools and machines)

- Support spare part structure for machines (BOM structure in SAP Business One)

- Preemptive maintenance / calibration for machines, equipment and tools (time based, counter based, task list definition, or multiple cycle definition with alert options, e.g. VDE cycle, testing cycle, own cycle, etc.)

- Generate maintenance orders in SAP Business One (report time and material consumption, maintain test specifications, e.g. for calibration, label printing after maintenance / calibration, maintenance reports/queries, e.g.detailed history/records, certification reports and others

- Exceptional maintenance (including notification reception directly from a shop floor terminal or handheld)

- Integration into ELO (Data Management Solution) to maintain documents (Excel test templates linked to equipment & orders)

- Handling of goods within containers / pallets in a warehouse or distribution center

- Provides a storage group extension

- Ability to print labels

- Perform transactions using containers

- Streamline and automate the warehouse process

WHY DO CLIENTS CHOSE US AS A MANUFACTURING PROVIDER?

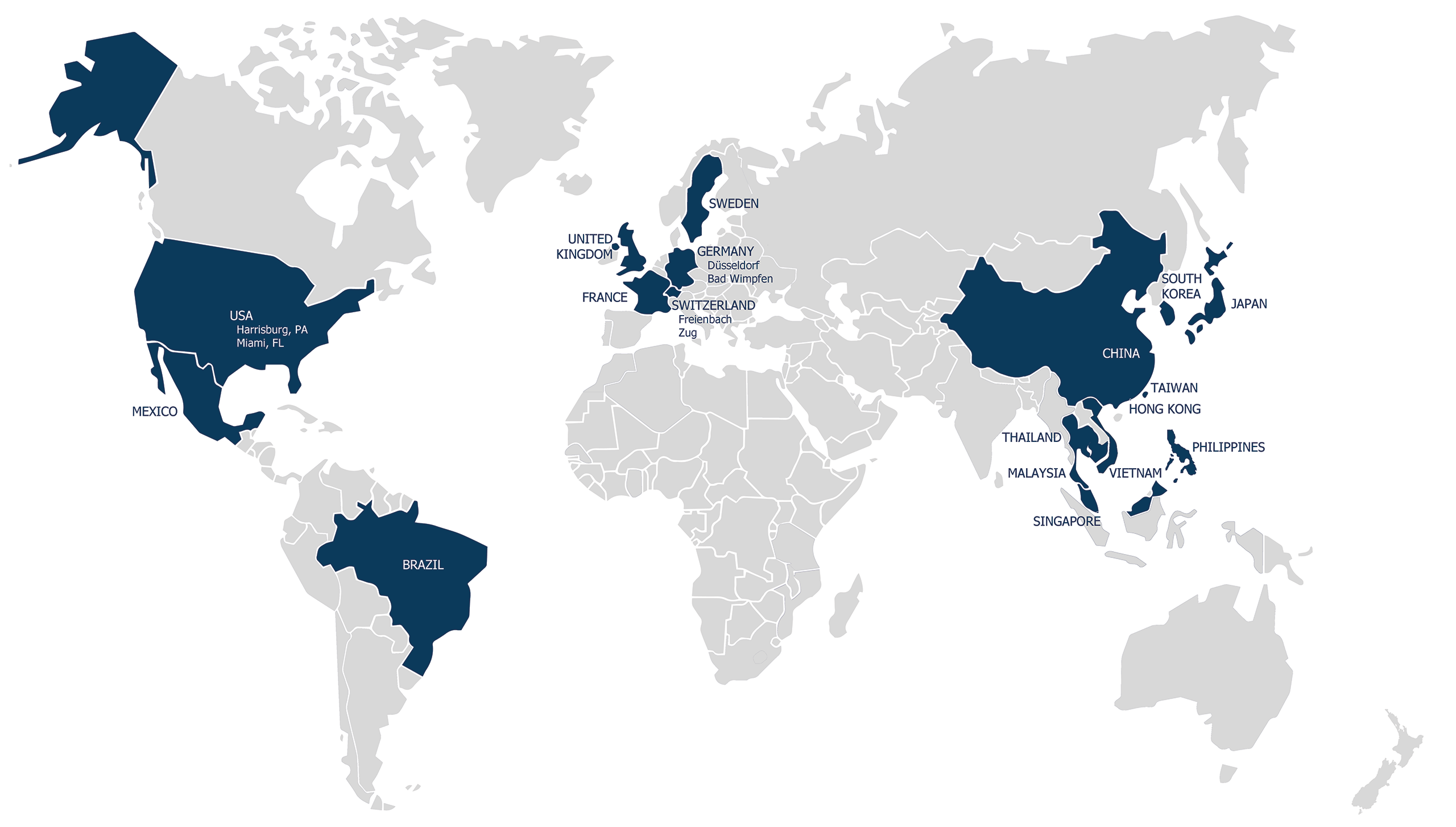

be one solutions is one of the biggest global SAP partners, specializing in successful worldwide blueprints, implementation, and support. Our wide experience comes with a wide experience implementing our very own solutions as well as a great variety of other ones which are available on the market.

MORE ABOUT SAP BUSINESS ONE

MORE ABOUT BE ONE SOLUTIONS

Our Other SAP Business One Add-ons

Don't let the performance of your business be impacted due to the lack of a Warehouse Management System (WMS) anymore. Our exclusive solutions address the challenges your warehouse encounters.

Dealers and distributors need to be able to communicate through simple and transparent systems. be one DMS (Dealer Management System) takes the relationship to the next level with our intuitive and cloud-enabled Dealer Management System.

We speak Automotive. We understand the complexities the automotive industry face including the challenges of local subsidiaries and we build ERP solutions with SAP Business One that fits our clients' global and local needs.

Thank You for Your Interest!

Our team will be in touch with you as soon as possible to discuss your needs and how we can help.

In the meantime, please feel free to explore our website or contact us again if you have any further questions.

You won’t want to miss be one solutions‘ next webinar. Add your email address to be notified :

Please select your language

Welcome on be one solutions‘ websites.

Please select your language.